KED Build #001 (S54B33) – Part 4

It’s been a busy few weeks, with plenty of work happening on the M3 that will be home to KED engine #001. The entire rear end of the car is currently in the air to allow for a new fuel tank, fuel lines and brake lines to be fitted. All of the rear suspension has been stripped down and is being re-painted.

In terms of visual updates, the steering wheel has been re-trimmed, and some carbon goodies from our friends over at Burkhart Engineering have also landed for the car.

The new pistons also arrived to go with the Arrow rods. More on these soon.

The cylinder head and valves were cleaned, the valves were lapped back in and the head is now ready for building back up.

Also, the Hack Engineering Billet Exhaust Hangers were anodised for a stealthier appearance, and the KED oil filter lids are progressing nicely.

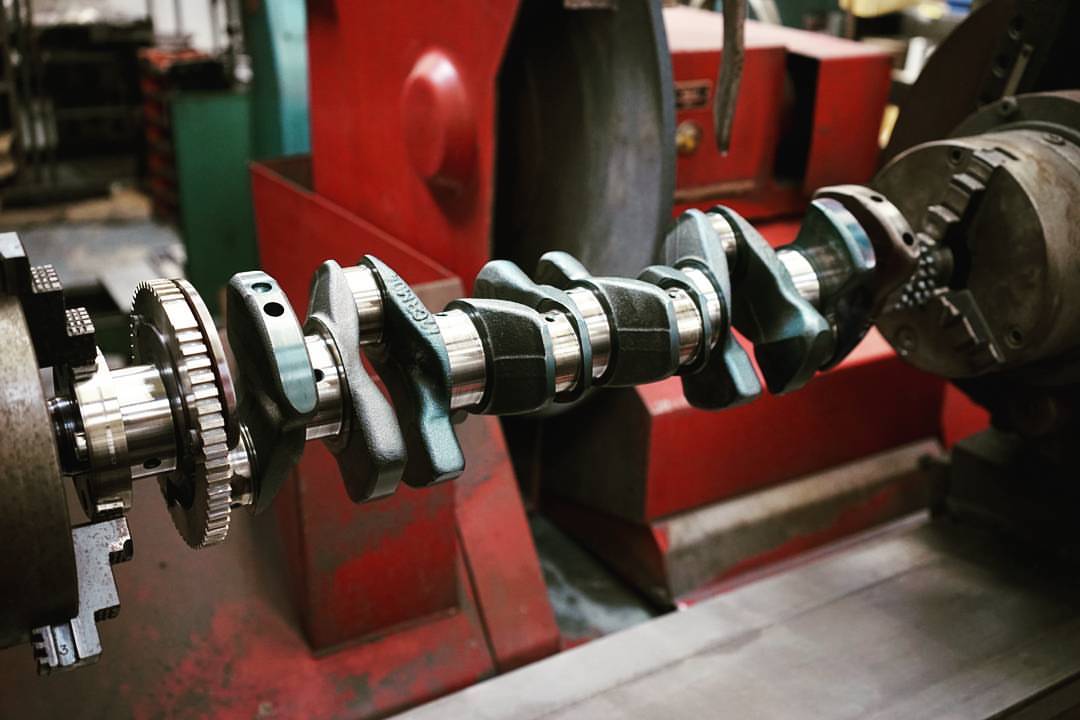

Lastly, the crank is currently receiving a full regrind. Upon closer inspection, it was found that the mains weren’t all running true (there was about 0.1 run out). There also appeared to be some fairly serious scoring here too, which didn’t polish out as expected. The big ends are also being re-ground due to shell damage to a few of them – an all-too common condition with S54 cranks.

We’re incredibly lucky to have some world-class local machine shops. Due to the way this crank grinder works, we were able to discover that there was nearly 0.5mm of variation between big end throws! We will be testing more S54 cranks to see what tolerances on these are like.

Unlike the majority of crank grinders, the one seen above doesn’t just ‘follow’ the journal that’s already there. It offsets the crank then indexes round, which means all of the big ends could be brought closer to optimal alignment.

KED Build #001 (S54B33)

- Introduction

- Part 1

- Part 2

- Part 3

- Part 4

- Part 5